- Home

- Thin Cut Machine

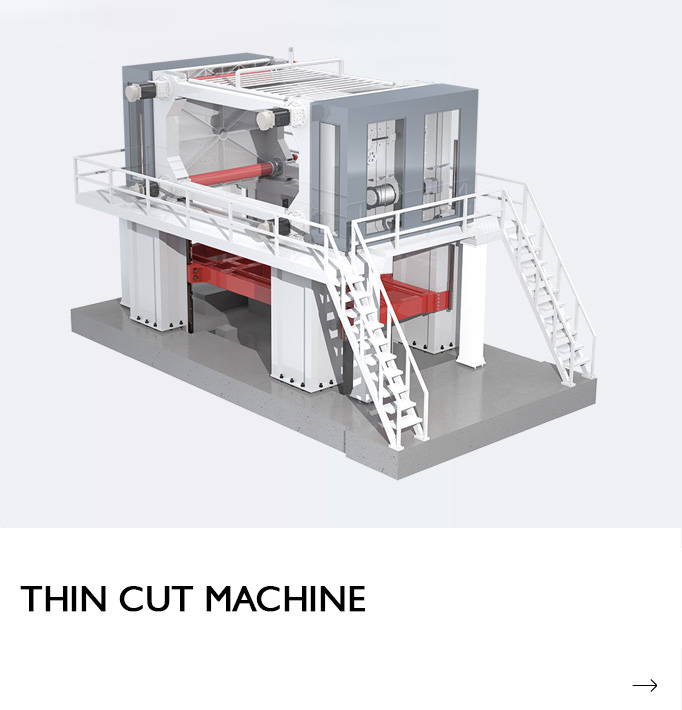

THIN CUT MACHINE

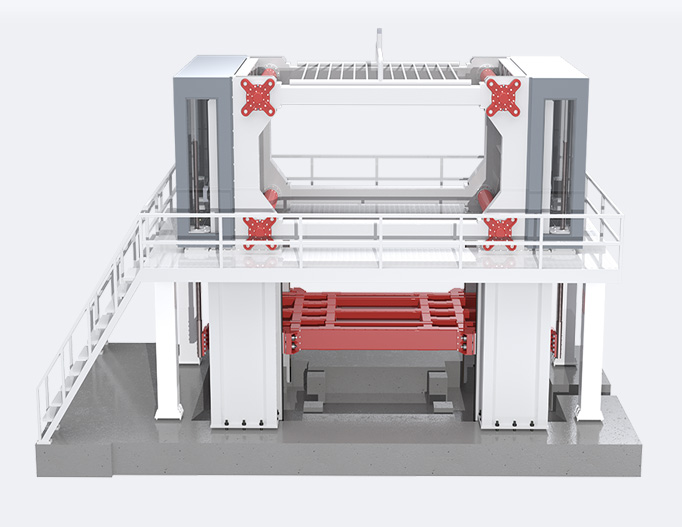

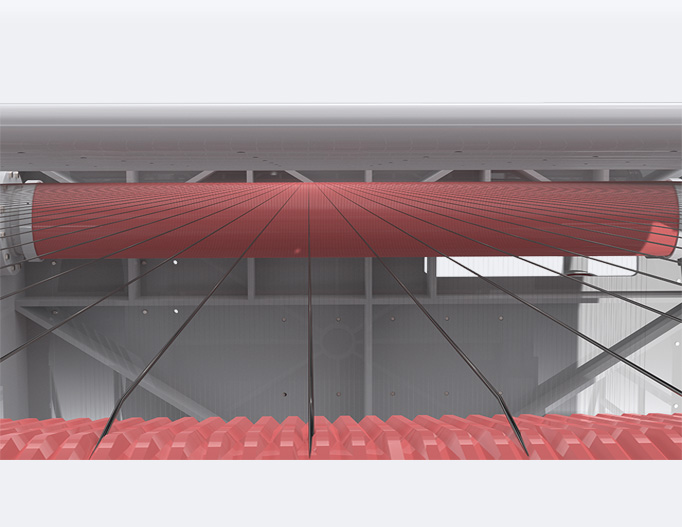

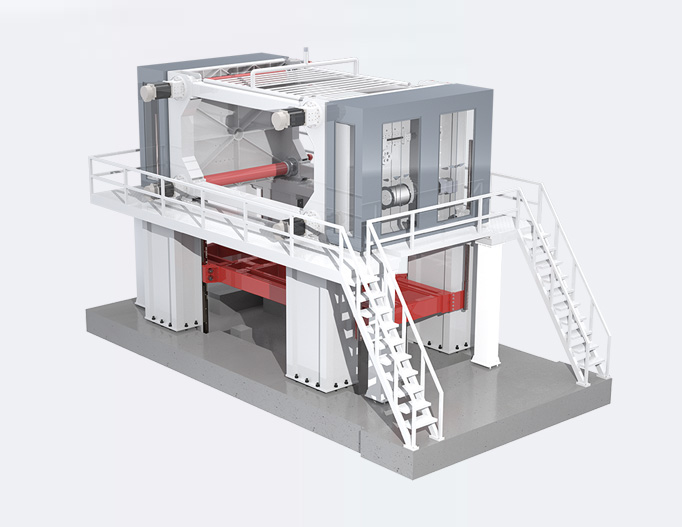

KMT-MULTI THIN WIRESAW is a groundbreaking marble-cutting machine designed for precision, efficiency, and high performance. As India’s first manufacturer of this advanced machine, it features ultra-thin diamond-electroplated wires (0.5–0.8 mm) that enable clean and accurate cuts, reducing material wastage while delivering high-quality results. Powered by Servo Motor Technology, the machine ensures smooth operation, exceptional control, and superior energy efficiency, making it an ideal choice for modern marble manufacturers.

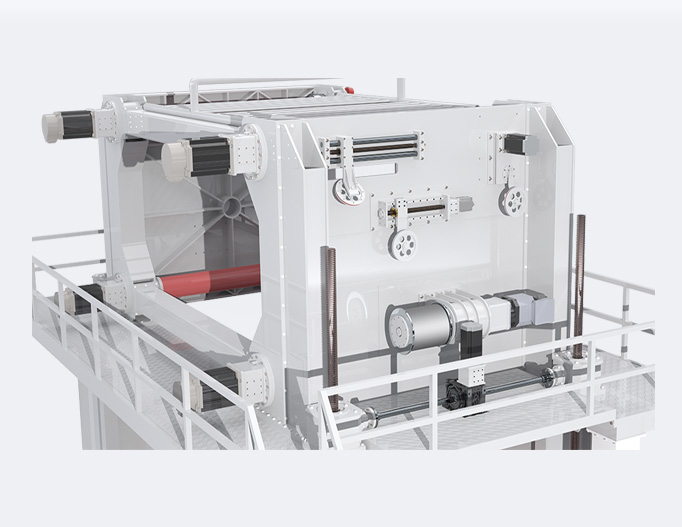

With a wire length range from 30 km to 80 km and the ability to handle marble blocks up to 3200 mm (length) × 2100 mm (height) × 2100 mm (width), KMT-MULTI THIN WIRESAW offers exceptional versatility. Its robust motor system with high-performance Servo Motors across all components, including the Main Drum, Spool, Tensioner, and Up/Down Mechanism, ensures seamless and efficient cutting.

Additionally, KMT-MULTI THIN WIRESAW incorporates trolley lifting, a design element that enhances performance compared to traditional frame-down wire saw machines. Trolley lifting provides increased stability and cutting speed, with the machine reaching RPMs exceeding 2000 and a cutting speed of 28-30 meters per second, outperforming frame-down machines. The stationary cutting head minimizes wire breakage and improves cutting accuracy. It also allows for better observability and quality control, enabling operators to monitor the process more effectively. Furthermore, the reduced movement of critical components results in lower maintenance costs and increased machine longevity.

KMT-MULTI THIN WIRESAW's enhanced stability, higher cutting speeds, and improved performance on hard materials make it an excellent choice for efficient and precise marble cutting. A live demo unit at the R&D facility showcases its capabilities in real-time, giving clients a firsthand experience of its performance.

KEY FEATURES

Experience optimized efficiency with our intelligent motor operation, activating main motors precisely when needed. Our strategic use of overpowered motors minimizes ampere loads, enabling us to achieve greater depths at higher speeds for unmatched production rates.

By opting for bushes over linear motion bearings, we offer five times the lifespan, ensuring long-term reliability and durability. Our use of screws instead of hydraulic systems not only prevents breakdowns caused by oil leaks but also enables our machines to achieve faster laps, maximizing efficiency and productivity.

Experience effortless cutting through even the toughest materials with our engineered solutions. By distributing weights onto two separate beams and providing precise RPM to set of blades, we've eradicated the issue of segments getting locked in hard granite. This breakthrough not only ensures seamless operation but also makes it effortless for our cutter to slice through the hardest materials with ease.

Choose us for machinery that's a breeze to operate, empowering operators to effortlessly set parameters with precision. Our user-friendly interface simplifies the process, ensuring seamless adjustments for optimal performance.

SPECIFICATION

TYPE |

MULTI THIN WIRE SAW |

|

LENGTH OF WIRE |

40 (KILOMETER) |

|

MAXIMUM |

LENGTH (mm) |

3200 |

HEIGHT(mm) |

2100 |

|

WIDTH (mm) |

2100 |

|

MOTORS POWER |

MAIN DRUM |

60 KW * 4 NOS |

SPOOL |

18 KW * 2 NOS |

|

TENSIONER |

7 KW * 2 NOS |

|

UP / DOWN |

7 KW * 2 NOS |

|

WINDING AND PAYOFF |

1 KW * 2 NOS |

|

The technical data (dimensions and weight) provided in the above table are not binding. We reserve the right to introduce and bring alterations without any prior notice to the customer.