- Home

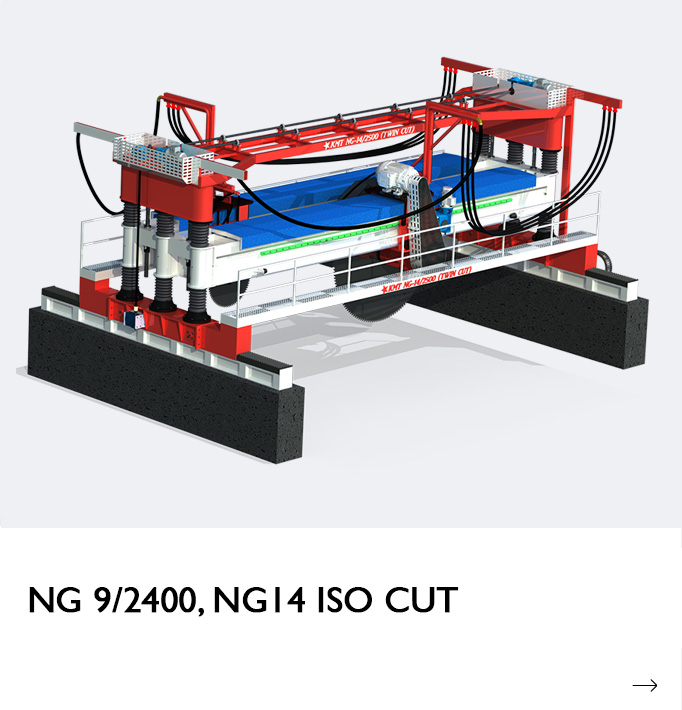

- NG 9/2400, NG14 ISO CUT

NG 9/2400

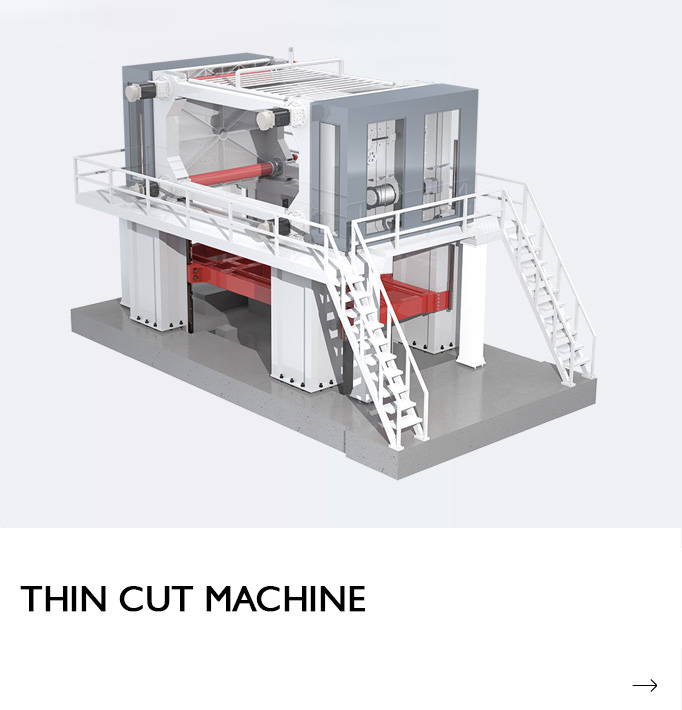

Introducing the pinnacle of multi-blade cutting technology: KMT NG-9/2400 Engineered to perfection by Karm Machine Tools, this revolutionary cutter is the epitome of efficiency, productivity, and cost-effectiveness.

NG 14 ISO CUT

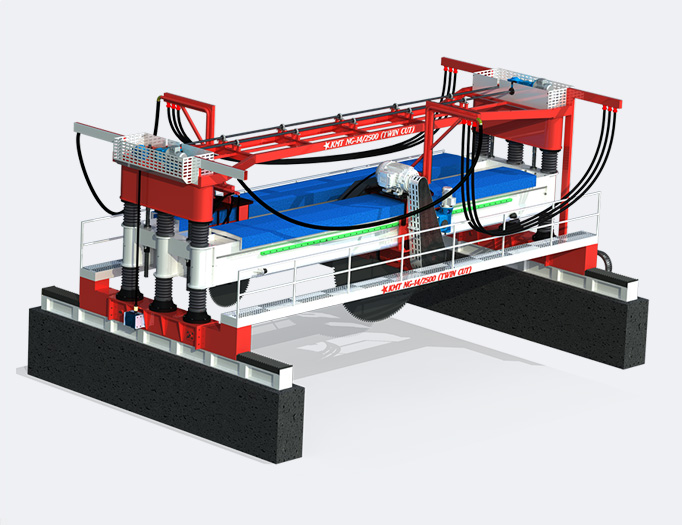

Introducing the pinnacle of multi-blade cutting technology: KMT NG-14 ISO Cut. Engineered to perfection by Karm Machine Tools, this revolutionary cutter is the epitome of efficiency, productivity, and cost-effectiveness.

With our innovative dual housing design and advanced side-entering technology, The ISO Cut Range delivers unparalleled performance.

Experience maximum output with minimal resources as our cutter optimizes production, slashes costs, and enhances efficiency.

Months of meticulous research and development by our dedicated team have culminated in this game-changing solution. Join the forefront of innovation with KMT’s ISO Cut Range and elevate your cutting operations to new heights.

DUAL HOUSING

- Experience the power of dual housing with the KMT ISO Cut Multi Cutter Range, Featuring not one, but two housings, this cutting-edge technology revolutionizes your cutting operations.

- Customized RPMs for each set of blades, evenly distribute blade weight, and exert precise control like never before.

KEY FEATURES

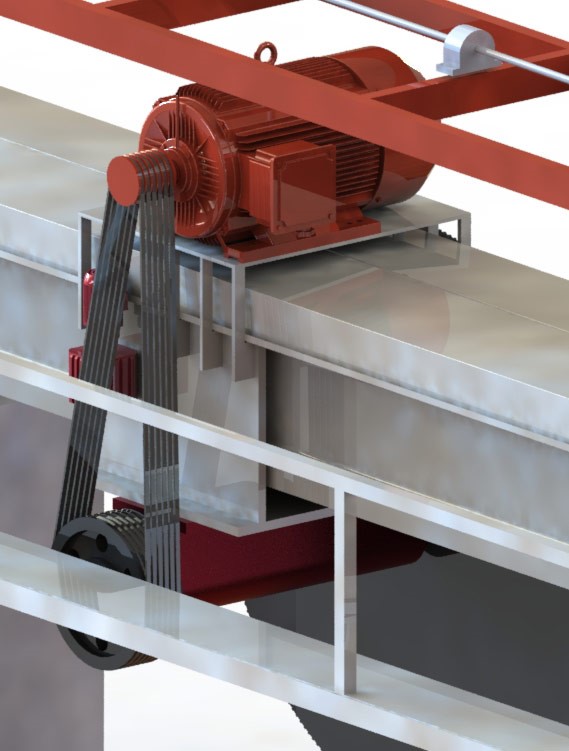

Housing transmits the torque generated by the main motor to the blade assembly. It also changes the torque and speed depending on the loads on the blade assembly.

NG-9/2400 : 9 OR 10 Blades

Ng5/3000 : 5 Blades

This motor provides rotary motion to the Housing via a set of belts and pulleys.

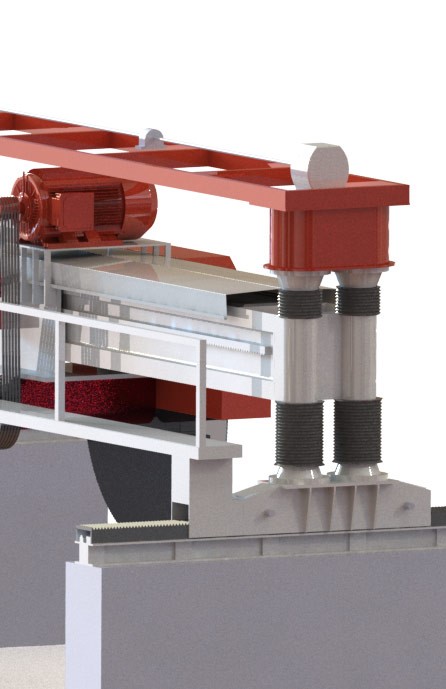

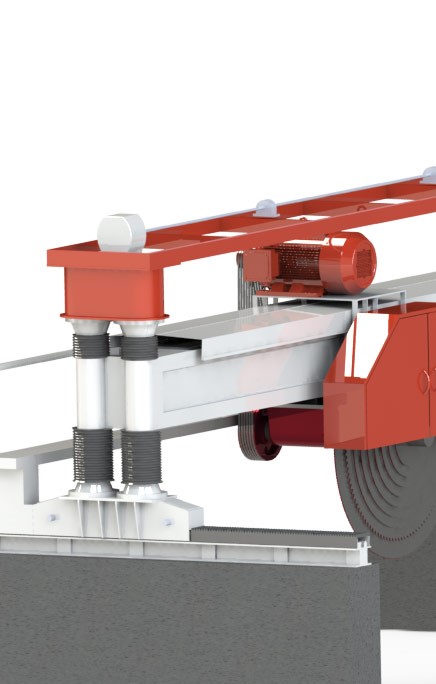

The whole blade assembly is mounted on this box. It provides horizontals movement to the blade assembly.

Column assembly consisting of two chrome platted pipes on the each side (4 pipes in total). Column assembly provides vertical linear motion to the beam. Chrome plated columns also ensures the high-precision, high-rigidity, energy-saving, high-speed motion with long service life.

SPECIFICATION

NG-9/2400

TYPE |

KMT NG-9/2400 |

|

NUMBER OF BLADES |

9 |

|

USEFUL CUTTING SIZE |

LENGTH (mm) |

3300 |

HEIGHT(mm) |

1000 |

|

WIDTH (mm) |

2000 |

|

MOTORS POWER |

MAIN (HP) |

75 HP 1400 RPM |

BEAM (UP/DOWN) |

5 HP 1440 RPM |

|

HYDRAULIC |

3 HP |

|

BEAM LT |

2 HP |

|

LENGTH OF BEAM |

8.5 (m) |

|

CYCLE PER MINUTE |

325 |

|

WEIGHT OF THE MACHINE |

17000 kg. (Approx.) |

|

DIMENSIONS OF TROLLEY |

2100 X 3050 |

|

The technical data (dimensions and weight) provided in the above table are not binding. We reserve the right to introduce and bring alterations without any prior notice to the customer. |

||